Okoume plywood, often called mahogany plywood, is an African hardwood. It is light brown in color, sometimes lustrous, with variable interlocked grain. Okoume panels exhibit high strength to weight ratios, ideal for boat building. Face veneers are 2.3 mm thick, A/B grade, and rotary cut. Cores and crossbands are solid jointed and panel glued with waterproof/boil proof glue. Marine grade okoume meets or exceeds British Standard 1088. Okoume panels are extensively used by race class boat builders, rowing shell builders, and in various applications where its light weight, high tensile strength, good bonding properties and ease of finishing are of value. On this Penobscot, we'll do the hull planking, bulkheads, and transom in okoume.

All of the interior wood will be either Phillipine or African mahogany. The Phillipine mahogany is a beautiful honey brown when finished and will match the okoume planking nicely. It will be used as structural lumber to build the hull, the longitudinal stringers, the stem, the bulkheads, and the keel.

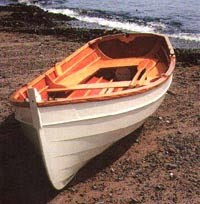

African mahogany is a deep, rich, burgundy-brown which will compliment the more subtle interior tones and be a stunning contrast to the white exterior. It will be used for the seats, gunwales, breast hook, and quarter knees.

The deadwood will be of white oak which is an excellent boat building wood. It is very tough and takes fastenings well. Due to its closed cell structure, which inhibits the intrusion of water, it is ideal for the one piece of wood on the boat that will remain submerged during normal use.

The combination of okoume, Phillipine mahogany, and African mahogany on this scale will be beautiful.

Our local lumber supplier quoted a four week delivery time for the okoume, so we contacted a well known boat lumber supplier in the Northwest--Edensaw Lumber in Port Townsend, Washington (www.edensaw.com). They did have some on hand and it should arrive within three to four days. In the meantime, we purchased the mahogany and the white oak as well as some pine for the frames and the building jig from High Desert Hardwood in Eagle, Idaho.

Row, row, row your boat...life is but a dream.